Based in South Canterbury, Farmers Mill is the only independent grower-owned and operated flour producer in New Zealand.

Primarily sold in 20kg sacks, Farmers Mill’s proudly NZ-grown and NZ-milled flour products are sold around the world. Since 2013 they’ve grown a reputation for their exceptional baking ingredients.

Such unwavering standards in products require equally focused expertise and commitment in packaging.

Starting with refining their bulk bag design, and more recently, working through an upgrade to their 20kg paper sacks, Smart Pack is proud to have collaborated on innovative changes to their packaging.

Farmers Mill takes pride in their paddock to pantry traceability, and has carefully grown their capacity here through continued investment in the latest and best milling equipment. Traceability at this scale is a major competitive advantage for food producers, particularly in export markets.

So when one major international customer commented that they were having issues with thread contamination in their operations, Farmers Mill acted quickly to remedy the situation. Smart Pack was called in to examine both product and process to ensure any issues could be effectively quashed.

“… the cost of life is significantly cheaper. That’s because we don’t have people sorting out issues at the other end – so we can focus on our product.”

Phil Jackson, Farmers Mill

Working with the Smart Park technical team, Farmers Mill replaced their stock-standard bulk bags with a bespoke design – one that could confidently uphold their incredibly high product standards and commitment to traceability.

Eliminating stitching and threads altogether, the updated design is now seamless. The new approach removes the risk of thread contamination, sifting, or leakage and, with a fully coated fabric, protects grain from moisture without requiring a liner.

Farmers Mill’s General Manager Phil Jackson appreciated the innovative approach to problem-solving to the Smart Pack team during the process of transforming the bulk bag design.

He acknowledges that examining the process from an objective position has resulted in better outcomes throughout the production process.

“Yes, it [the new packaging] was a little bit dearer, but the cost of life is significantly cheaper,” he says. “That’s because we don’t have people sorting out issues at the other end – so we can focus on our product.”

The new bulk bags are also a better shape and size for the product, optimising Farmers Mill’s supply line.

“Storage is better, damage is much less, customers are happier and freight is much easier,” says Phil.

With the new bulk bags in place and performing well, Smart Pack was called in to assess another key packaging product where stock standard bag sizing was slowing things down – their paper flour sacks.

Moving from a generic size to a bag designed specifically for the Farmers Mill systems led to greater efficiencies in filling, storage and transportation.

It also presented the opportunity to refresh the sack design, evolving the aesthetic to more effectively convey the company’s story and South Canterbury heritage.

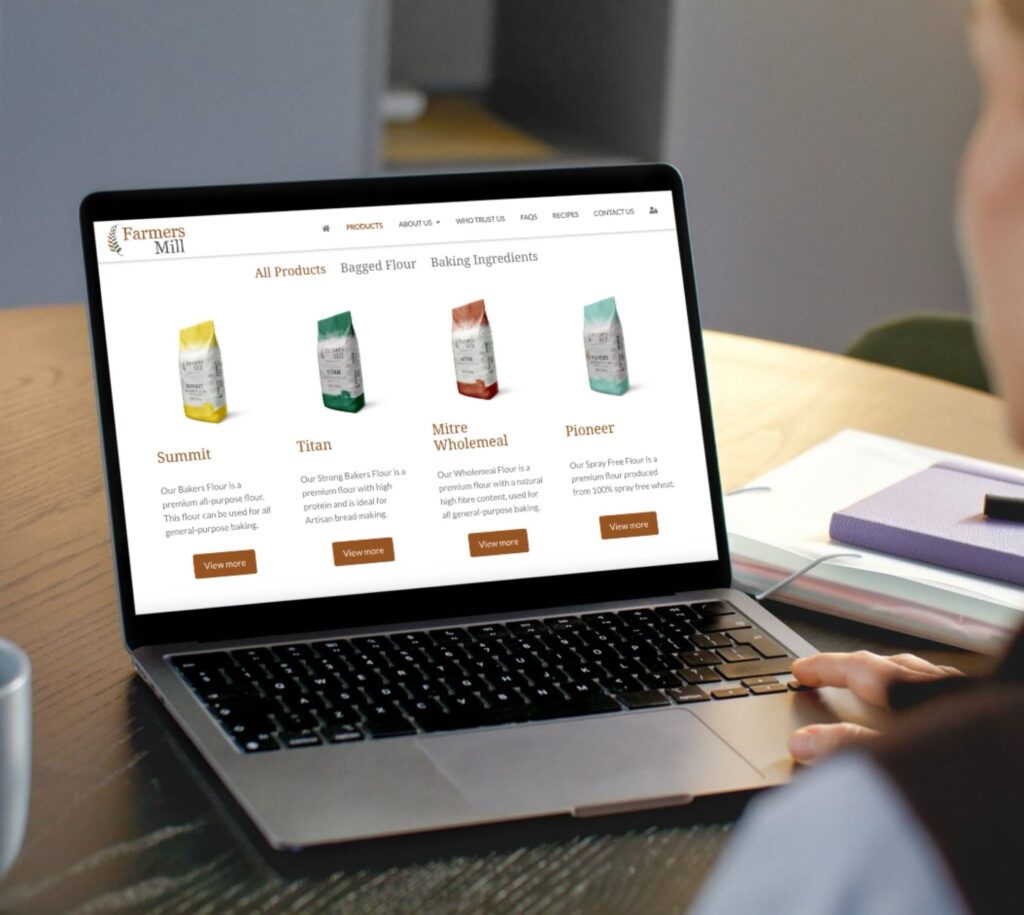

Smart Pack’s design team created a new look for the sacks, bringing in a palette of subtle, soft colours to clearly differentiate between products. Harsh line and block colours were replaced by silhouettes of the products’ origins – the fields in which the grains are grown and harvesters at work.

An additional colour at the top of the flour sacks now helps distributors and busy bakers find what they need quickly.

“Before, we had a bag with a name on it,”says Phil. “Now we have a bag that tells a story.”

The new design was such a hit that it’s become an important feature of the website look and feel, too.

By working closely with the Smart Pack team, Farmers Mill has transformed its flour sacks and bulk bags to reduce damage, remove contamination, and improve the supply line from bagging to freight.

Communication has been a key reason behind the success of the change. It also underpins the new inventory management system, with fortnightly forecasting meetings now in place to track bag usage and forecast supply levels.

This ensures the busy mill doesn’t run out or, conversely, end up with too much stock. For Phil Jackson, it’s another way Smart Pack makes life easier.

“The inventory management side of things means my team focuses on what we’re good at. Producing flour and selling flour.”