Bulk bags are commonly used to transport and store granulated and fine powdered materials. However, if risks are not properly assessed and mitigated, this practice can cause the build-up of an electrostatic charge – with shocking and sometimes explosive results.

There are five main types of static shock (or electrical discharge that can occur in bulk bag packaging – sparks, brush discharge (energy discharged from nonconductive surfaces), propagating brush discharge (a charge builds up on an insulated surface), bulking brush discharge (a charge from the surface of charged dust or powders), and corona discharge (when the air is ionised around an electrical conductor).

The risk for many of these shock types is compounded when there are solvents, gas or fine powder in the atmosphere. Any spark from an electrostatic discharge in the bag can ignite these elements, with catastrophic consequences.

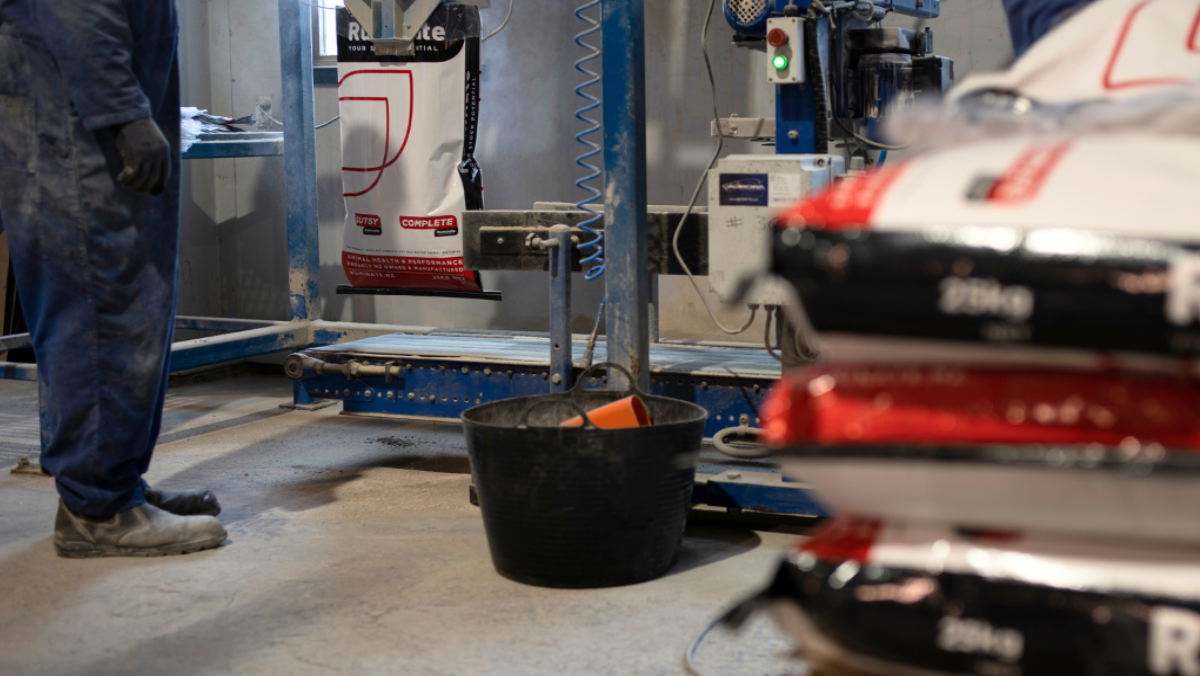

“There’s an energy build-up that occurs anywhere there is powder and friction against a surface,” says Smart Pack’s Leon Currie. “Everyone who has worked in a feed mill will know about risk mitigation plans for static build-up in silos – the same process can be just as important on a smaller scale too.”

What bulk bag is right for my operation?

For many companies the occurrence of static discharges poses a very low risk – but it’s still a risk all the same. Australasian businesses need to therefore be certain they are using the right type of bulk bag for their specific materials.

Flexible Intermediate Bulk Containers (FIBCs), most commonly known as bulk bags, come in four types:

Type A FIBCs are non-conductive and usually made from plain woven polypropylene. When powdered materials move or rub against the bag, especially when they are being filled or emptied, electrostatic discharges can be ignited. For this reason, Type A bags should not be used for moving combustible loads, or in situations where flammable gases are present.

Type B FIBCs are also non-conductive and made from plain-woven polypropylene. However, Type B bags can prevent propagating brush discharges. These types of bags can still cause annoying shocks to workers (which can lead to other serious accidents). Contaminants can also be attracted to the bag’s surface, causing problems with emptying the bag. These bags shouldn’t be used when flammable solvents or gases are present.

Type C FIBCs are made from non-conductive polypropylene fabrics interwoven with conducting threads, which must be grounded when being filled or emptied. These threads are usually sewn in a grid pattern and must also be electrically interconnected when grounded. If properly used these bags can safely transport flammable powders even when gases, dust and vapours are present in the atmosphere.

Type D FIBCs are made from fabrics containing quasi-conductive threads, which means they safely dissipate static electricity through low-energy corona discharge. These threads don’t need to be interconnected or grounded, reducing the risks posed by human error. This means that like Type C bags, they can be used to transport flammable powders even when gases, dust and vapours are present in the atmosphere. Workers should watch out for any contamination or coating of conductive material such as grease on the bags, which could prevent safe discharge from occurring.

Bulk bag liners can further reduce electrostatic discharges. These come in three types: L1 (conductive), L2 (static dissipative), and L3 (insulating). The choice of liner will again depend on the material being transported as well as the atmosphere surrounding it. Risk profiling will help determine the best choice for a particular product.

Health and safety precautions

Risk profiling should be carried out before any work is done, to ensure the right types of bags and equipment are in place. If assessments show a minimum ignition energy from your loads of more than 50mJ, grounded bulk bags should be used and staff should also be provided with grounding wrist straps and footwear to prevent shocks. Anti-static flooring or conductive mats will further reduce the risk of injury.

“Occasionally we still come across a ‘she’ll be right’ mindset,” says Leon. “It doesn’t matter what you’re bagging – proper risk profiling still needs to occur. Thankfully, health and safety management processes are now driving decision-making, which means peace of mind for everyone.”

Smart Pack can supply anti-static bulk bags both with and without a liner. Get in touch with our team to help determine what bags are right for your operation,