With a bigger focus on sustainable products and processes, more Australian and New Zealand businesses are looking at packaging options that best match their environmental objectives.

As a packaging partner we are always expanding our offering to accommodate these considerations. To add to our recyclable packaging options, we can offer polyethylene (PE) Open Mouth and Valve Bags.

If considering a change to Open Mouth PE Bags, there are a few important areas to be aware of. This is where a packaging partner can help you find a solution for your specific needs. For now here are some of the main points to preface:

Filling LDPE (Low density polyethylene) bags is very similar to common industrial agriculture bags and can often be done on existing machinery designed for woven polypropylene (WPP) or multi-wall paper (MWP) bags. However, you may find some LDPE (low density polyethylene) bags are not as rigid which means automated machinery may need to be adjusted slightly to accommodate the change in bag material.

LDPE bags are heat-sealed closed which results in a strong and air-tight seal. Your production targets and your current equipment will need to be considered to reach your specific output goals. Contact us for a list if automation machinery suppliers.

PE bags have lower anti-slip properties compared to other packaging therefore may be more likely to move when stacked compared to WPP and MWP bags. However, with current technologies there are small changes that can be made to the specification and construction to ensure minimal movement when stacking. It is also recommended, dependant on the product going in the bag, that you add perforations or punch holes so the air can be released as fast as possible to keep a consistent stack pattern.

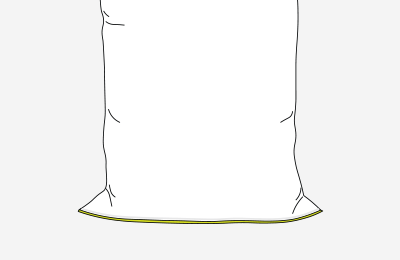

The original bag construction - simple and functional

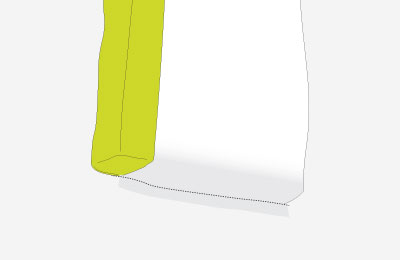

The Gusset Construction looks attractive and improves stacking performance

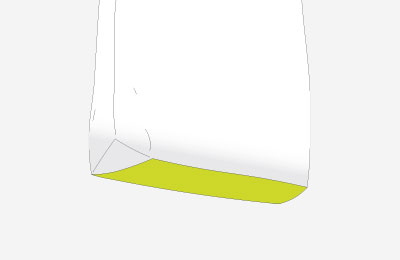

Awesome option for high-stacking performance and added printing area on the base.

Valve PE bags are also an excellent option for all interested and have a range of customisation possibilities to meet your needs.

Full-graphic printing can be utilised for optimal branding exposure as well as simple and time-efficient methods such as our in-house flexographic printing (up to 5 colours).

100% recyclable in New Zealand and Australia if the bag is thoroughly cleaned out and returned to a facility with recycling capacity.

The price will typically depend on the construction, material, printing, and quantity of your bags. You can usually see the cost of PE bags sitting between that of WPP and MWP.

Smart Pack are the experts when it comes to PE bags and can cover all the above and more so you can have confidence when making the switch.