Feeling the strain of freight delays and rising costs? Here’s how you can maximise container space and reduce loading times through optimising your bulk bags.

The cost of international freight continues to rise, therefore it’s important that we utilise any and every space within containers – no one likes paying for air to be transported across the ocean!

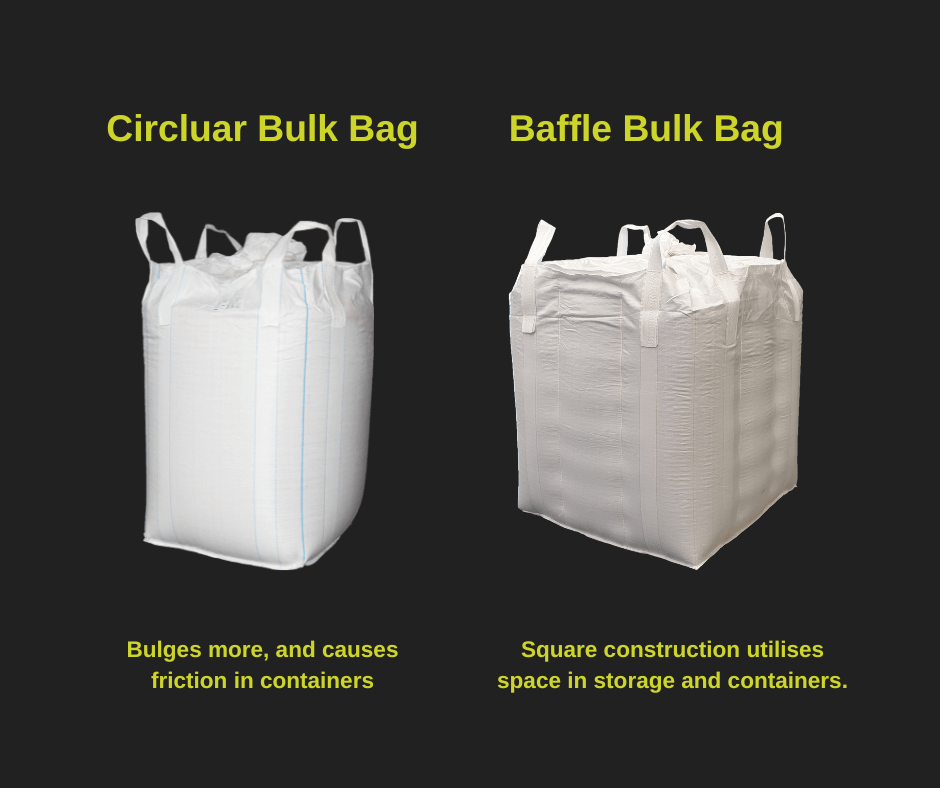

For export, we recommend a baffled bulk bag in most cases as they hold their square shape for maximum utilisation of space and stability when transporting.

When selecting your bulk bag size, consider the following points:

Baffled bulk bags have a squarer shape and hold their form well which is why they stack better than circular bulk bags.

Not all bulk bags are created equal. The quality can make a significant difference to the loading speed and the amount of space it needs within the container.

It’s important to partner with a supplier who you know can supply high quality bulk bags that hold their form, to ensure you are receiving bags that meet your specific requirements, every time. Ask your supplier to check the following elements.

Whatever industry you’re in, if you’re exporting product in bulk bags, having a packaging partner that understands every part of the process from manufacturing to export, can save you time, money and stress, now, and down the line.

Want to explore how you can export your product more efficiently? Get in touch with the team today!